26 Sep How Do You Calculate Wire Rope Size

Hey there, curious minds! Have you ever found yourself in a situation where you needed to choose the right wire rope size but felt completely lost in the sea of options? Don’t worry; you’re not alone. Selecting the correct wire rope size can be a bit puzzling, but fear not! In this guide, we’ll walk you through the process in plain English, making it as easy as choosing the perfect slice of pizza.

Think of wire ropes as the unsung heroes of various industries. They’re like the strong, reliable muscles that lift, pull, and secure loads ranging from elevators in skyscrapers to massive shipping containers on cargo ships. So, let’s roll up our sleeves and dive into the world of wire ropes.

Understanding Wire Ropes

Before we jump into the nitty-gritty of selecting the right wire rope size, let’s start with the basics. What exactly is a wire rope, and how does it work?

What’s a Wire Rope?

Imagine a wire rope as a bundle of tiny steel wires twisted together to create a strong, flexible, and durable cable. It’s like a necklace made of steel wires instead of beads. These steel wires, also known as strands, are wound around a central core, typically made of fiber or another material depending on the application. When attaching the wire rope to an object or another rope, wire rope clamps can be used. To select the right clamp, consulting a wire rope clamp size chart is important. This chart can help determine the appropriate size based on the diameter of the rope.

How Does It Work?

Wire ropes work like a team of tiny superheroes. When you apply force or tension to one end of the rope, the individual wires distribute the load evenly, ensuring that no single wire bears the entire burden. This makes wire ropes incredibly strong and reliable.

Factors to Consider

Now that you have a basic understanding of what wire ropes are, it’s time to delve into the factors you should consider when choosing the right size. Picking the correct wire rope size isn’t a one-size-fits-all deal; it depends on several key factors.

1. Load Weight

Think of your wire rope as a bridge. Just like different bridges can handle varying weights of vehicles, wire ropes come in various sizes to handle different load weights. The weight your wire rope needs to support is a crucial factor in determining its size. If you overload a wire rope, it’s like driving a semi-truck over a footbridge – not a good idea.

2. Diameter

Wire ropes come in a range of diameters, from thin and wiry to thick and robust. The diameter of the rope affects its strength. Thicker ropes are stronger and can handle heavier loads, while thinner ones are better suited for lighter applications. So, consider the diameter in relation to your load.

3. Construction

Wire ropes come in different constructions, such as 6×19, 7×19, or 7×7. These numbers indicate the arrangement of strands and wires in the rope. Each construction type has its own set of properties and is suitable for specific tasks. It’s like choosing the right tool for the job – a hammer for nails, a wrench for bolts.

4. Material

The material of the wire rope matters. Common materials include galvanized steel, stainless steel, and carbon steel. Your choice depends on environmental conditions and the rope’s intended use. For example, stainless steel is great for resisting corrosion in marine environments.

Calculating the Right Wire Rope Size

Alright, now that you know the factors to consider, let’s crunch some numbers. Calculating the right wire rope size may seem daunting, but it’s not rocket science. Think of it as figuring out the right amount of ingredients for your favorite recipe – you just need the right formula.

Step 1: Determine the Load Weight

Before you can select the right wire rope size, you need to know how much weight or force the rope will be subjected to. This is your starting point, and it’s critical to get it right. Underestimate, and you risk rope failure; overestimate, and you’re overspending on a larger rope than you need.

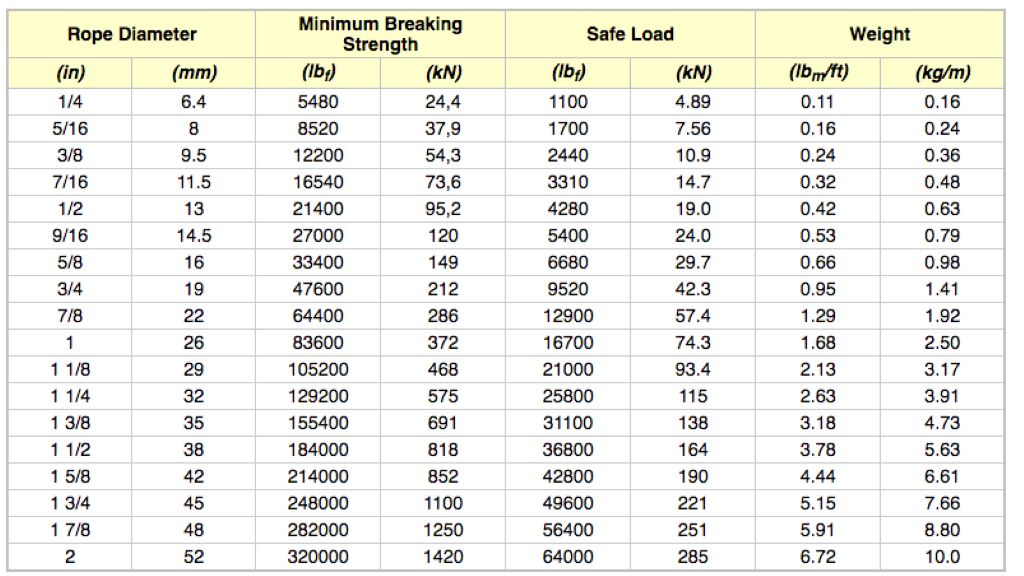

Step 2: Calculate the Minimum Breaking Strength (MBS)

The Minimum Breaking Strength (MBS) is the maximum load a wire rope can handle without breaking. This is where the rope’s diameter comes into play. To calculate the MBS, you’ll need to refer to the manufacturer’s data or consult industry standards and guidelines.

For instance, if you have a load of 10,000 pounds, you’d want a wire rope with an MBS that exceeds this weight. Let’s say the MBS of a particular wire rope size is 15,000 pounds. That’s a good fit for your application.

Step 3: Select the Right Diameter

Now that you know your load weight and the MBS required, you can select the appropriate wire rope diameter. The diameter you choose should have an MBS comfortably higher than your load weight.

Keep in mind that wire ropes aren’t just about meeting the bare minimum; it’s about safety and durability. Going a bit larger on the diameter can provide an extra margin of safety, much like wearing a size bigger shoe for comfort.

FAQs

Now that we’ve covered the basics of selecting the right wire rope size, let’s address some common questions that might be lingering in your mind.

1: Can I use any wire rope size for my application?

No, you can’t. The wire rope size you need depends on several factors, including the load weight, diameter, construction, and material. Using the wrong size can be dangerous and lead to rope failure.

2: How do I know the load weight for my application?

You’ll need to assess the specific requirements of your task. If you’re unsure, consult with an engineer or a professional who can help you determine the load weight accurately.

3: Can I use a smaller diameter wire rope to save money?

It’s not advisable. Using a wire rope with a smaller diameter than required can compromise safety and lead to accidents. It’s better to choose the right size based on load weight and other factors.

4: Are there any safety precautions when using wire ropes?

Absolutely! Regular inspection, maintenance, and proper installation are crucial for wire rope safety. Always follow manufacturer recommendations and industry standards.

5: Can I use a wire rope for lifting and lowering heavy loads vertically?

Yes, wire ropes are commonly used for vertical lifting and lowering applications. However, make sure to choose the right size and construction type suitable for the specific task, and follow safety guidelines.

Conclusion

Choosing the right wire rope size might seem a bit overwhelming at first, but it’s like solving a puzzle. You just need to gather the pieces – load weight, diameter, construction, and material – and put them together to find the perfect fit. Remember, safety should always be your top priority.

So, the next time you’re faced with the task of selecting a wire rope size, approach it with confidence, just like you would when picking your favorite ice cream flavor. With the right knowledge, you’ll have your wire rope working smoothly, lifting heavy loads, and securing your projects without a hitch. Happy roping!

Sorry, the comment form is closed at this time.