08 Feb How Much Do Titanium Surgical Screws Weight? Unveiling the Weight of Medical Marvels

Titanium screws are commonly used in medical procedures such as orthopedic surgeries to provide stability and support to broken or damaged bones. If you’re curious about the weight of these screws, you’ll discover that they generally range from 1 to 5 grams. Titanium surgical screws typically weigh between 1 to 5 grams. Welcome to our article on the weight of titanium surgical screws!

The use of titanium in surgical screws is highly favored in the medical field, as highlighted by Heartandstylewoman, due to its exceptional attributes. Titanium stands out for its remarkable strength, durability, and biocompatibility, making it an ideal material for surgical applications. One key aspect of titanium surgical screws that merits further exploration is their weight. Despite being incredibly strong, titanium is notably lightweight, which is a significant advantage in medical procedures. This lightweight nature reduces the overall stress on the body, particularly in areas requiring multiple screws, such as complex fractures or spinal surgeries.

The reduced weight does not compromise the strength or stability provided by these screws, ensuring they can effectively stabilize bones during the healing process. Additionally, titanium’s biocompatibility means that it is less likely to cause adverse reactions within the body, making it a safe choice for long-term implantation. The use of titanium surgical screws is therefore crucial in various medical applications, offering a balance of lightweight design and robust performance.

The Importance Of Lightweight Surgical Screws

Advantages Of Lightweight Screws

When it comes to surgical procedures, the weight of titanium surgical screws plays a crucial role in the success of the surgery and the patient’s recovery. Titanium surgical screws are preferred for their lightweight properties, which bring numerous benefits to both patients and surgeons.

- Reduction in Tissue Damage: Lightweight screws exert less pressure on surrounding tissues, reducing the risk of damage during and after surgery.

- Minimized Stress on Bones: A lighter weight reduces the stress on the bones, promoting better healing and reducing the risk of complications.

- Easier Handling for Surgeons: Surgeons find it easier to manipulate and position lightweight screws during surgery, allowing for greater precision and accuracy.

- Lower Risk of Implant Failure: The use of lightweight screws minimizes the risk of implant failure, leading to improved long-term outcomes for patients.

Impact On Patient Recovery

The weight of surgical screws directly impacts the recovery process for patients undergoing orthopedic procedures. The use of lightweight titanium screws contributes significantly to the overall recovery and healing process, leading to better post-operative outcomes.

- Quicker Rehabilitation: Lighter screws reduce the strain on the affected area, facilitating a faster rehabilitation process for the patient.

- Enhanced Comfort: Patients experience less discomfort and pain due to the reduced pressure exerted by lightweight screws.

- Improved Mobility: The use of lightweight screws allows for improved movement and mobility during the recovery phase, aiding in the restoration of normal function.

Understanding Titanium As The Ideal Material For Surgical Screws

When it comes to the field of surgical implants, titanium has emerged as the ideal material for a variety of applications, including surgical screws, which play a crucial role in orthopedic procedures. One key aspect to consider in the use of surgical screws is what happens when a surgical screw comes loose, a situation that can affect the stability of the implant and the success of the surgery. In this article, we will explore the properties of titanium that make it a standout choice for surgical screws, as well as the numerous benefits it offers in medical applications. This discussion will include its biocompatibility, strength, and resistance to corrosion, all of which contribute to its reliability and effectiveness in surgical settings.

Properties Of Titanium

Titanium possesses several remarkable properties that make it highly suitable for surgical screws. Let’s take a closer look:

- Lightweight: Titanium is known for its exceptional strength-to-weight ratio, making it a lightweight option for surgical screws. This lightweight property minimizes the overall weight burden on the patient during the healing process.

- Biocompatible: One of the key reasons titanium is used in medical applications is because it is biocompatible. This means that it is well-tolerated by the human body and poses minimal risk of adverse reactions or rejection. Titanium’s biocompatibility ensures better compatibility with the surrounding tissues, promoting faster healing and reduced complications.

- Corrosion-resistant: Titanium is highly resistant to corrosion, even in the presence of bodily fluids. This is particularly important in surgical applications, where the implant needs to withstand the body’s natural environment for extended periods without degrading or causing harm.

- High strength: Despite its lightweight nature, titanium possesses impressive strength. This strength contributes to the stability and durability of surgical screws, reducing the likelihood of breakage or failure.

Benefits Of Titanium For Medical Applications

The use of titanium in surgical screws offers numerous benefits for medical applications. Consider the following advantages:

- Reduced risk of complications: Titanium’s biocompatibility and corrosion resistance greatly minimize the risk of complications, such as infections or allergic reactions, that can arise from the use of other materials.

- Enhanced healing: Titanium’s compatibility with the body’s tissues allows for improved healing. This can lead to faster recovery times, reduced pain, and improved overall patient outcomes.

- Long-lasting performance: Titanium surgical screws have a long lifespan due to their strength and resistance to corrosion. This reduces the need for additional surgeries or replacements, saving both time and resources.

- Compatibility with medical imaging: Titanium is non-magnetic and does not interfere with medical imaging techniques such as MRIs or CT scans. This enables healthcare professionals to obtain accurate and reliable images, facilitating proper diagnosis and treatment planning.

Exploring The Weight Of Titanium Surgical Screws

When it comes to surgical procedures, precision and durability are crucial. Titanium surgical screws are widely used in orthopedic surgeries due to their exceptional strength, corrosion resistance, and biocompatibility. But have you ever wondered how much these tiny screws weigh? In this article, we will delve into the weight of titanium surgical screws, comparing them to traditional materials and exploring the factors that affect their weight.

Comparing Titanium Screws To Traditional Materials

Titanium screws have revolutionized the field of surgery by offering a range of advantages over traditional materials like stainless steel and cobalt-chromium alloys. One significant advantage is their weight. Titanium is known for its remarkable strength-to-weight ratio, making it a favored choice in various industries, including the medical field.

- Titanium screws are significantly lighter than stainless steel screws, reducing the overall weight and strain on the patient during the healing process.

- The lightweight nature of titanium screws also provides added convenience for the surgeon, allowing for easier handling and manipulation during the procedure.

Moreover, the reduced weight of titanium screws helps minimize the risk of implant fatigue and improves the long-term success of the surgery.

Factors Affecting Titanium Screw Weight

The weight of titanium surgical screws can vary depending on several factors. Here are some key factors that can affect their weight:

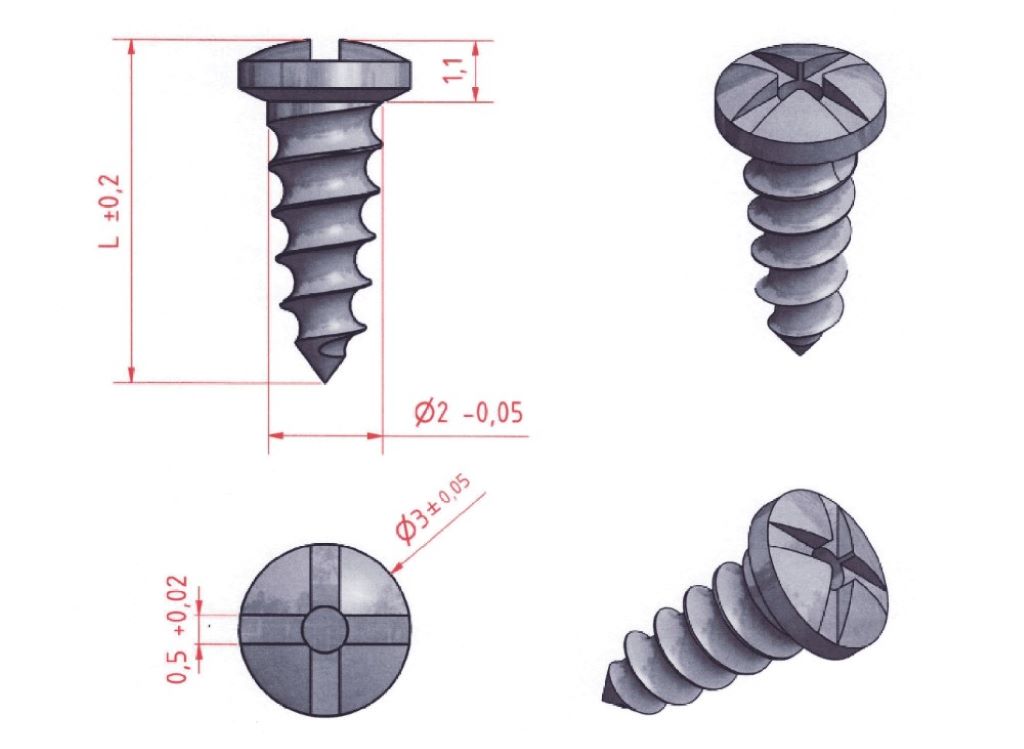

- Size and Length: The size and length of the screw play a significant role in determining its weight. Larger screws will naturally weigh more than smaller ones.

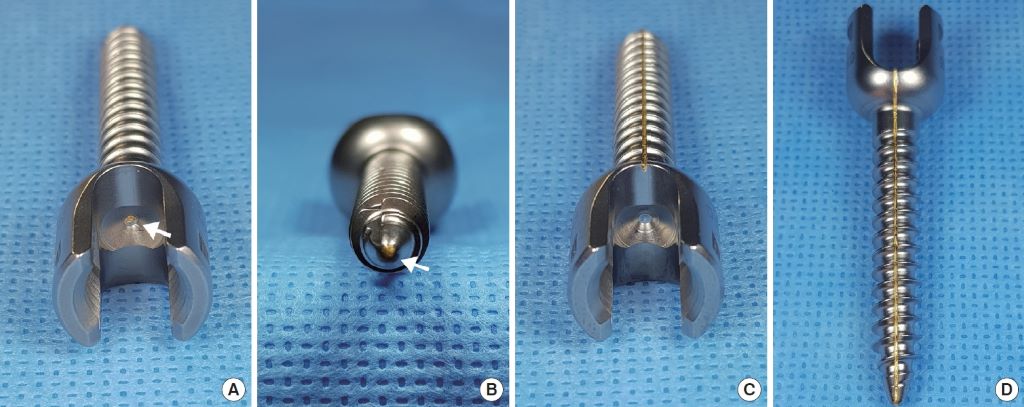

- Design: The design of the screw, including the thread pattern and head shape, can impact its weight. Different designs are tailored to specific surgical applications and patient needs.

- Alloy Composition: Titanium alloys with different compositions can have varying densities, affecting the weight of the screw. The most commonly used alloy for surgical screws is Ti-6Al-4V, known for its excellent strength and lightweight characteristics.

- Surface Coatings: Some titanium screws may have specialized coatings, such as hydroxyapatite, to promote osseointegration and stability. These coatings may add a slight amount of weight.

It’s worth noting that while titanium screws are lightweight compared to traditional materials, their weight still ensures stability and strength, providing effective support for bone fixation and repair.

Case Studies: Weight Comparison With Other Medical Implants

Comparison With Stainless Steel Implants

When we compare the weight of titanium surgical screws with stainless steel implants, titanium screws are significantly lighter, making them a favorable choice for orthopedic and dental surgeries.

Comparison With Cobalt-chromium Implants

In contrast to cobalt-chromium implants, titanium surgical screws weigh much less, offering the advantage of reduced implant load on the patient’s body, ensuring enhanced post-operative comfort and recovery.

Future Innovations In Lightweight Medical Implants

Advancements In Titanium Alloys

Titanium surgical screws have revolutionized the field of medical implants due to their remarkable properties. With the demand for lightweight and highly reliable implants on the rise, researchers and engineers are constantly pushing for advancements in titanium alloys. These advancements aim to improve the overall performance and weight reduction of surgical screws, ensuring better patient outcomes and greater comfort during the healing process.

One significant advancement in titanium alloys is the development of beta titanium alloys. These alloys exhibit higher strength-to-weight ratios, making them extremely attractive for medical applications. By incorporating elements such as aluminum and vanadium, researchers have successfully enhanced the mechanical properties of titanium screws while still maintaining their biocompatibility.

Another exciting innovation is the use of nanotechnology in titanium alloys. By manipulating the size and arrangement of titanium particles at a nanoscale level, the mechanical properties of the screws can be significantly enhanced. These nano titanium screws offer superior strength and durability compared to conventional titanium implants. Additionally, their reduced weight allows for easier implantation and faster recovery time for patients.

Exploring Alternative Lightweight Materials

While titanium alloys have proven to be highly effective, researchers are also exploring alternative lightweight materials to further improve medical implant technologies. One such material is biodegradable polymers. These polymers offer several advantages, including their ability to degrade naturally in the body over time. This eliminates the need for additional surgery to remove the implants, reducing patient discomfort and complications.

Magnesium alloys are another promising alternative to titanium. They possess similar mechanical properties but are significantly lighter, which can lead to reduced implant weight and improved patient comfort. However, further research is required to optimize the degradation rate and biocompatibility of magnesium alloys for medical applications.

Composite materials are also being explored as potential lightweight alternatives for surgical implants. Composed of a combination of materials such as carbon fibers and epoxy resins, these composites offer excellent strength-to-weight ratios. Their customizable properties make them a viable option for specific medical implant requirements, providing surgeons with greater flexibility and versatility in their procedures.

Frequently Asked Questions On How Much Do Titanium Surgical Screws Weigh

What Are Titanium Surgical Screws And Their Weight?

Titanium surgical screws are medical implants used in orthopedic surgery to stabilize bones. These screws are lightweight to minimize patient discomfort and allow for quick healing. On average, titanium surgical screws weigh around 1. 5 grams, making them an ideal choice for medical applications.

How Is The Weight Of Titanium Surgical Screws Determined?

The weight of titanium surgical screws is determined by their size and dimensions. The length, diameter, and design of the screw influence its weight. Understanding the weight of these screws is crucial for surgeons to select the most suitable implants for their patients’ needs.

Why Are Lightweight Titanium Surgical Screws Preferred?

Lightweight titanium surgical screws are preferred for their biocompatibility, which reduces the risk of rejection or allergic reactions. Their low density also minimizes the burden on the patient’s body, promoting faster recovery and improved post-operative comfort. These factors contribute to their popularity in medical procedures.

Conclusion

The weight of titanium surgical screws is an important consideration in medical procedures. We’ve discussed the average weight range, which can vary depending on factors such as size and application. It’s crucial for healthcare professionals to accurately gauge the weight to ensure optimal patient outcomes.

Sorry, the comment form is closed at this time.